Superior Quality Control with a Vickers Hardness Tester

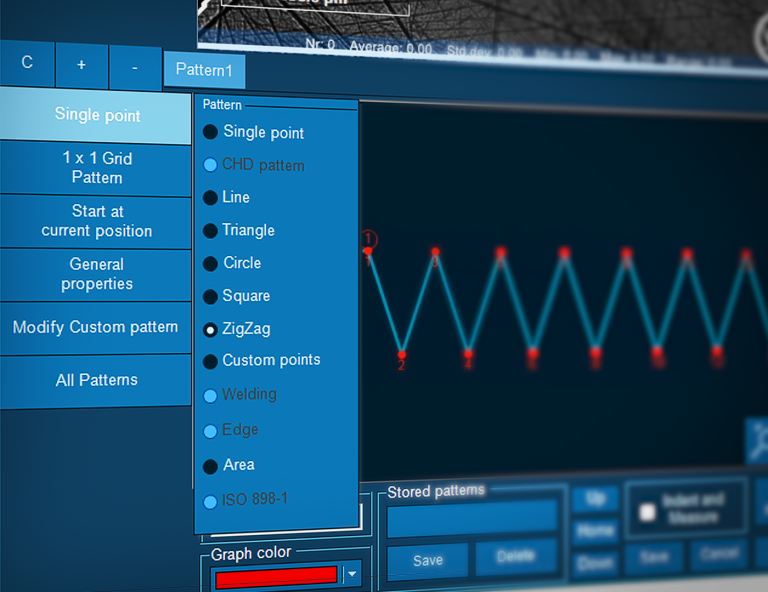

Metallographic research is critical in numerous industries, particularly manufacturing, and the type of equipment used matters a great deal. A Vickers hardness tester is one of the most popular tools. The hardness testers gauge the hardness of metals using the Vickers method. This system requires testing hardness using an indenter that resembles a four-sided diamond. The load has to be applied perpendicularly. Vickers testers are also called microhardness testers. Innovatest carries different models of Vickers testers that are designed to make hardness testing as accurate and convenient as possible. The equipment includes advanced features and technology like touchscreen interfaces, high-speed autofocus and cameras. You can choose from bench & floor models or portable testers.

The Versatility of Vickers Testing Equipment

One of the biggest selling points of Vickers hardness testing devices is that they work on soft and hard metals. Since calculations don’t depend on the size of the indenter, the hardness of the metal is irrelevant. You can get Vicker for a broad category of materials, including ceramics and composites. The equipment comes in handy in various other applications like measuring the surface of a part, testing foils and individual microstructures. Vickers testers apply to loads of between 1 kgf and 100 kgf. These devices also vary by the load application mechanisms. Direct load, stepper motor and lever-type are the main alternatives. The three mechanisms offer different accuracies with direct load testers being the most accurate, followed by stepper motor then lever-style models. Individual applications will dictate the right type.

Browse our range to find a Vickers hardness tester that suits your quality control requirements.